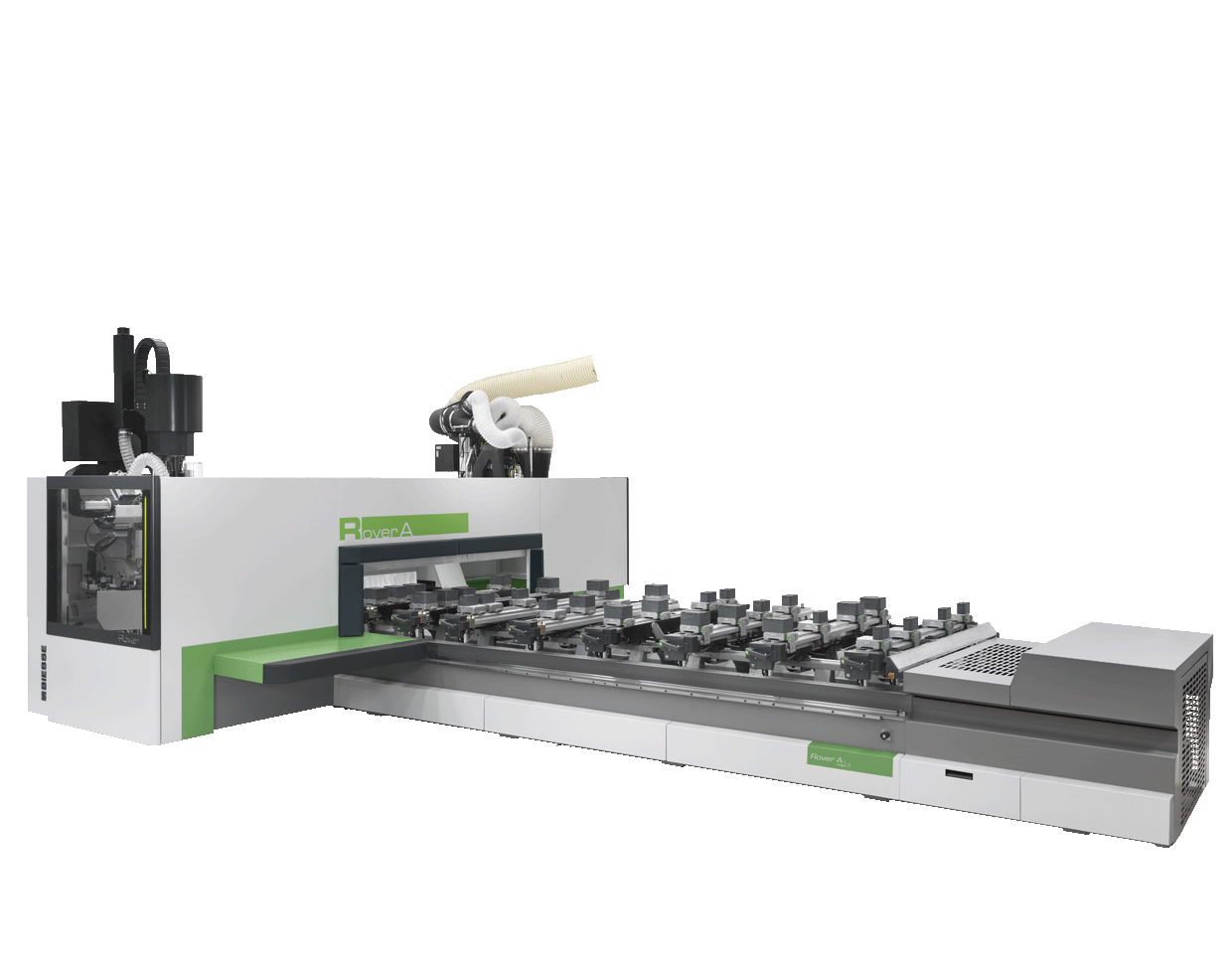

CNC machining center BIESSE ROVER A 1532 EDGE

CNC machining center ROVER A 1532 EDGE Working fields (vertical electrospindle axis reference):

X = 3140 mm;

Y = 1560 mm;

Z = 200 mm with H74 mm modules;

Z = 245 mm with H29 mm modules.

The Z values mentioned above are valid with tools with a maximum length of 170 mm

Edgebanding unit

6 ATS panel supports - 24 sliding bases

7 additional connections with quick coupling, to connect special jigs to the auxiliary vacuum system of the machine.

6 Stop of the back line with a stroke of 115 mm and extension of 25 mm.

6 Stop of the middle line, positioned at 685 mm, with a stroke of 140 mm.

6 Stop of the front line, positioned at 1348 mm, with a stroke of 140 mm.

4 Side stops with a stroke of 140 mm (2 Lh + 2 Rh) inclusive of the pneumatic system.

4 removable central stops with a stroke of 140 mm (2 Lh + 2 Rh) inclusive of the pneumatic system.

250 m3/h rotary claws vacuum pump

13.2 kW (17.7 HP) Electrospindle with HSK F63 adaptor and air cooling

360° rotation interpolating unit - Torque C-Axis

Boring head BH 17 L

6 positions Revolver Toolchanger, positioned on the Y axis carriage

Combined edge-trimming / edge-scraping / glue-scraping aggregate EF60C.

BSolid 3D CAD-CAM program to design, simulate and manage the machining processes

bEdge - module for the application and finishing of banding material

Net price of the device from

CNC machining center ROVER A 1532 EDGE

Working fields (vertical electrospindle axis reference):

X = 3140 mm;

Y = 1560 mm;

Z = 200 mm with H74 mm modules;

Z = 245 mm with H29 mm modules.

The Z values mentioned above are valid with tools with a maximum length of 170 mm

Edgebanding unit

6 ATS panel supports - 24 sliding bases

7 additional connections with quick coupling, to connect special jigs to the auxiliary vacuum system of the machine.

6 Stop of the back line with a stroke of 115 mm and extension of 25 mm.

6 Stop of the middle line, positioned at 685 mm, with a stroke of 140 mm.

6 Stop of the front line, positioned at 1348 mm, with a stroke of 140 mm.

4 Side stops with a stroke of 140 mm (2 Lh + 2 Rh) inclusive of the pneumatic system.

4 removable central stops with a stroke of 140 mm (2 Lh + 2 Rh) inclusive of the pneumatic system.

250 m3/h rotary claws vacuum pump

13.2 kW (17.7 HP) Electrospindle with HSK F63 adaptor and air cooling

360° rotation interpolating unit - Torque C-Axis

Boring head BH 17 L

6 positions Revolver Toolchanger, positioned on the Y axis carriage

Combined edge-trimming / edge-scraping / glue-scraping aggregate EF60C.

BSolid 3D CAD-CAM program to design, simulate and manage the machining processes

bEdge - module for the application and finishing of banding material